A Better Arthroscopic Probe

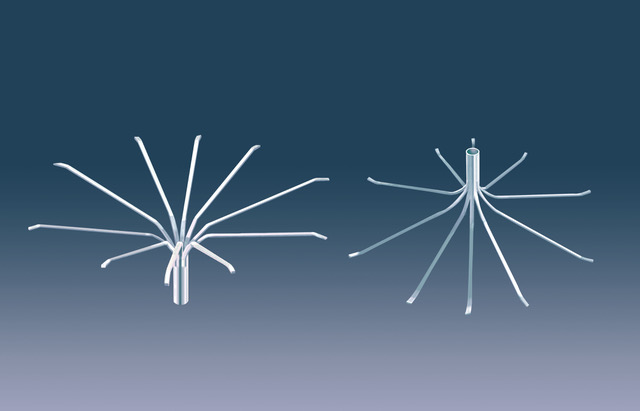

The surgical device designer wanted a thin, lightweight probe that a surgeon could push through an artery then pull back, allowing a dozen extensions to spring out, conforming to curved or irregular arterial surfaces. The probe’s extensions had to be thin enough to fit in the very narrow probe and then, when the probe was pulled back, flexible enough to conform to the surfaces.

We manufactured extensions in 0.006” stainless steel, cutting rectangular blanks 0.825” long. 12 narrow slits were cut parallel to the length of the blank and the unslit base of the blank was rolled into a closed tube. The slits were then bent outward in a heat-controlled atmosphere, forming an arrangement of durable extensions with an outward cast.

Working with the same principle, different probes with longer or shorter extensions or fewer extensions could be manufactured for different surgical situations.