Evans has processed millions of stainless steel pieces — austenitic, ferritic, martensitic and duplex. Services include in-house tooling and secondary operations. We are active in all kinds of industries, from defense and aerospace to medical and automotive.

The austenitic stainless steels are essentially nonmagnetic in the annealed condition and can be hardened only by cold working. They usually possess excellent cryogenic properties and good high-temperature strength and oxidation resistance. Even the leanest austenitic stainless steels (e.g., types 302 and 304) offer general corrosion resistance in the atmosphere, in many aqueous media, in the presence of foods, and in oxidizing acids such as nitric acid. Austenitic stainless steels offer excellent corrosion resistance in organic, acid, industrial and marine environments. The non-magnetic properties combined with exceptionally high toughness at all temperatures make these steels an excellent selection for a wide variety of applications.

Working on a project using austenitic stainless steel? If we can help, please click here.

Evans ammunition casing components have the enormous advantage of being drawn not from brass but from austenitic stainless steel, making them much lighter than brass casings, a critical military advantage. A highly complicated drawn part, the casing is tapered and the bottom is shaped to form an integrated rivet to which the primer base is attached. Evans’ design is specially formed, giving the casing additional compliance under high pressure. Evans casing components are used in casings for 4.6, 5.56 and 7.62 caliber cartridges.

Made of austenitic SS 304 stainless steel, this complex component is found in fire supression systems. The multi-step deep draw progression includes rolling, tapering, controlled orifice drilling, side piercing, diameter stepping and more, all meeting tight aviation/aerospace tolerances.

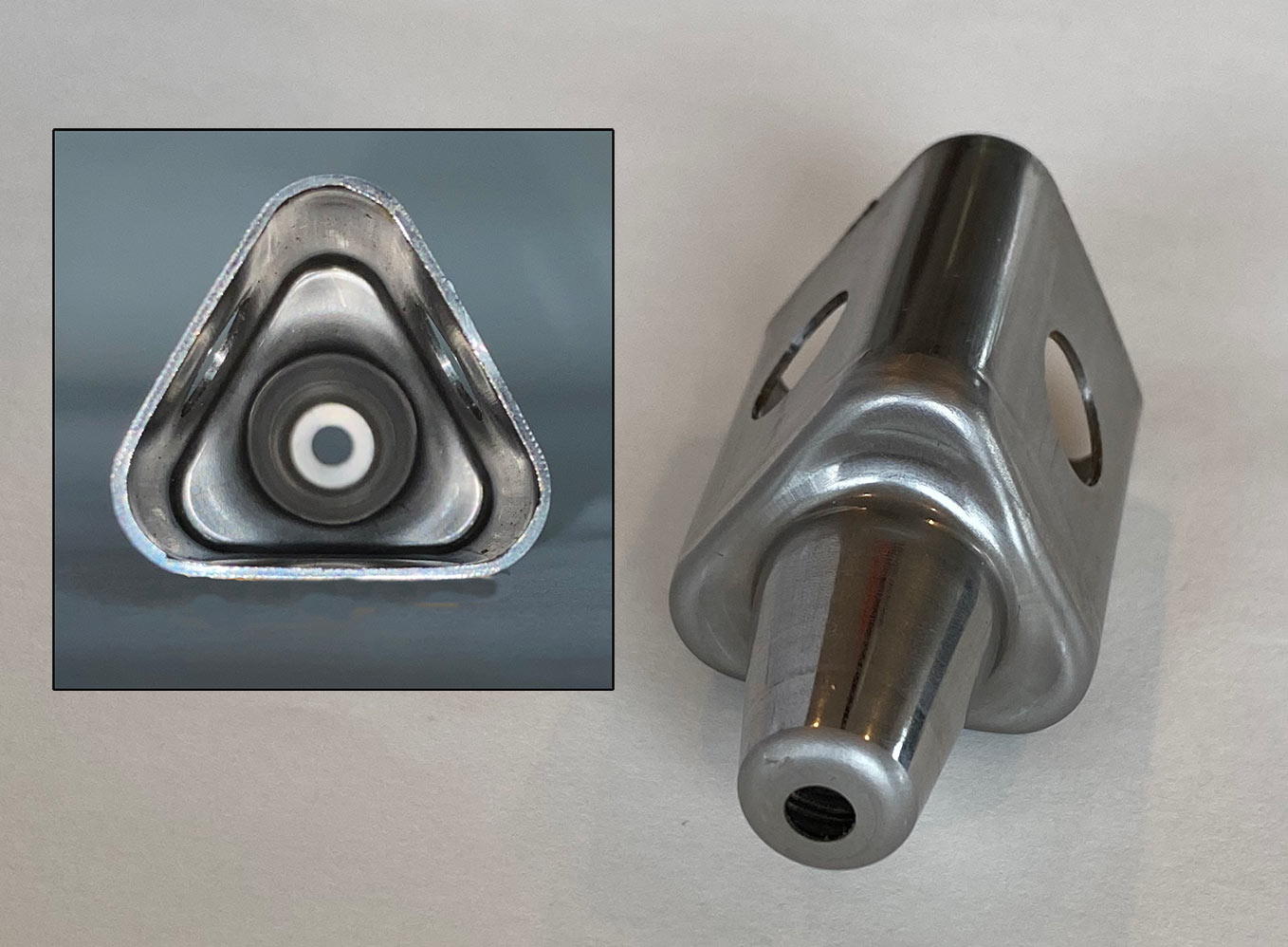

This unusual component for a burner system is SS 304 stainless steel. The cavities were perforated, then the flat steel was mandrel-formed in three steps before finishing.

This stainless steel can and cap enclose a pressure gauge used in food processing. The bezeled edge ensures a secure fit. The steel is heavy walled, requiring a 50-ton hydraulic press load. The side extrusion enables the pressure gauge housing to be welded to the pressure diaphragm.

This austenitic stainless steel check valve body is an automotive component. It is manufactured for fuel and anti-lock brake systems.