EDM Hole Drilling

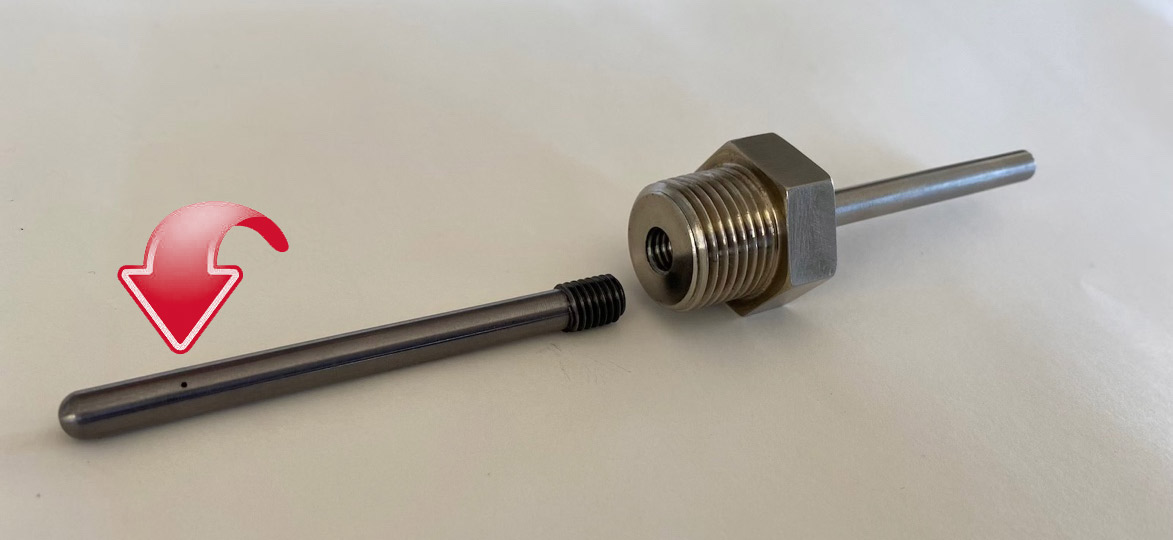

In addition to deep drawn and progressive die stampings, Evans offers a full complement of secondary operations and even some stand-alone procedures. EDM hole drilling is in demand both as a secondary operation and as a stand-alone machining operation.

As a secondary operation, we drill holes as small as 0.005” with tolerances as tight as 0.0002” With EDM we create similar holes in metals too hard or too thin for high accuracy drilling. We create intricate patterns of holes in both progressive die stamping and EDM hole drilling. EDM is usually used for shorter runs and in situations where contact with the metal is to be avoided. EDM can also create holes at unusual angles.

As with our other operations, our EDM hole drilling undergoes continuous quality control, meeting customer-specific standards. We comply with the Buy American Act and use only conflict-free raw materials.

Working on a project using precision drilling? If we can help, please click here.