Evans’ deep drawn and progressive die molybdenum stampings

Evans often stamps moly when high strength and low elasticity must be maintained in high temperature conditions. Molybdenum combines a high melting point (2610° C, or 4730° F) with strength retention at high temperatures.

Molybdenum also has a high specific elastic modulus, which makes it attractive for applications that require both high stiffness and low weight. The high thermal conductivity, low coefficient of thermal expansion, and low specific heat of this metal provide resistance to thermal shock and fatigue, and the properties are also important in electronic applications. In addition, molybdenum is stable in a wide variety of chemical environments, and it has good electrical conductivity, although this physical property is seldom the critical factor in metal selection.

Working on a project using molybdenum? If we can help, please click here.

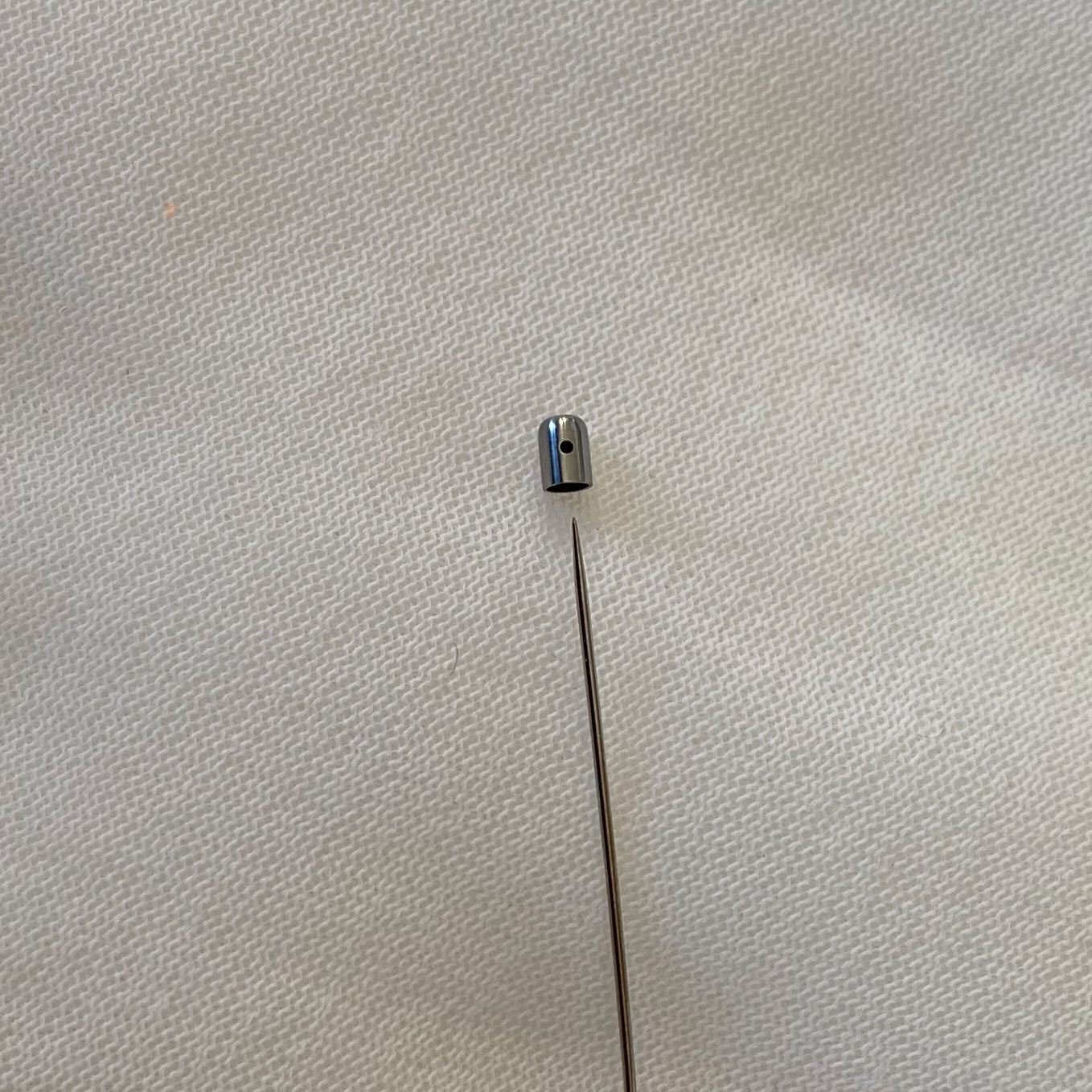

Deep drawn molybdenum is uncommon because of the metal’s forming and temperature-related limitations. Familiar with moly, however, Evans was able to perfect this miniature deep drawn molybdenum shell for aeronautics use. The moly shell is used in an ignition system. The side-piercing is 0.025” in diameter. The length is 0.2000”, with a 0.0005” tolerance.