Evans is the world’s leading manufacturer of deep drawn and progressive die tantalum stampings

Our tantalum pieces are known in aerospace and defense, electronics and general industry for their exceptional precision and conformance to specifications. We don’t know of anyone with more experience in deep drawn tantalum.

Tantalum provides a combination of properties not found in most refractory metals. Its high melting point (2996° C, or 5425° F), tolerance for interstitial elements, and reasonable modulus of elasticity make it an attractive alloy base material. Tantalum also possesses excellent room-temperature ductility (>20% tensile elongation) and is readily weldable. Commercially pure tantalum, tantalum-tungsten alloys, and tantalum-niobium alloys are widely used in capacitors and chemical-process equipment such as heat exchangers, condensers, thermowells, and lined vessels; most notably, it is used for the condensing, reboiling, preheating, and cooling of nitric acid, hydrochloric acid, sulfuric acid, and combinations of these acids with many other chemicals. Because of its high melting point, tantalum is used for heating elements, heat shields, and other components in high-temperature vacuum furnaces. Tantalum and its alloys have been used in specialized aerospace and nuclear applications and have found increasing use in military components (e.g., anti-armor weapon systems). Because of its corrosion resistance of body fluids, it is used in prosthetic devices, implants and surgical staples.

Among many other deep drawn and progressive metal stampings, we produce:

- Tantalum cans

- Tantalum caps

- Tantalum crucibles

- Tantalum cups

- Tantalum electrodes

- Tantalum eyelets

- Tantalum fasteners

- Tantalum ferrules

- Tantalum shells

Working on a project using tantalum? If we can help, please click here.

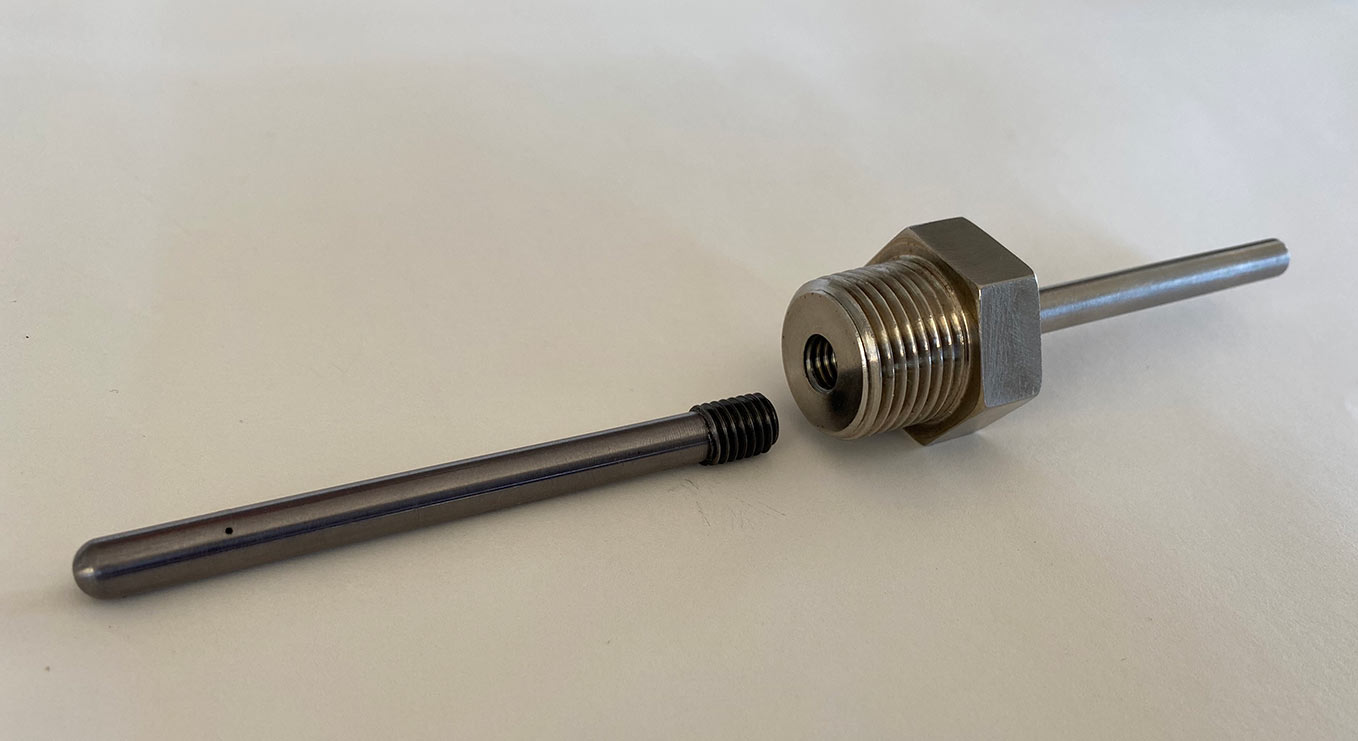

At one end of the Evans assembly is a tantalum tube, machined to be hollow but closed at the end. The tube is immersed in a harsh chemical that flows through a pipe. A small hole, side-pierced into the tantalum tube, allows a chemical sample to be drawn into the Evans assembly from the center of the flow.