Complex deep drawn and progressive die metal stampings

A few examples of solutions found with deep drawn and progressive metals stampings.

Sometimes a problem is solved by designing an uncommon shape.

Sometimes it is solved because of remarkable precision, achieved with proprietary machine tools.

The ability to apply advanced metal forming technology is extremely important in metal forming operations. In addition to complicated metal stamping operations, Evans drills, machines and finishes in numerous ways, and we can coordinate with others to perfect unusual secondary operations. For effective approaches and engineering solutions in formed metal components, we offer experience, imagination and enthusiasm, providing extensive customer support around the world.

This is an interesting example of designing and producing a new component that improves an existing application. In this case Evans designed and manufactured a two-piece stainless steel connector that allowed a manufacturer of stadium lights to make a more efficient light. Read more…

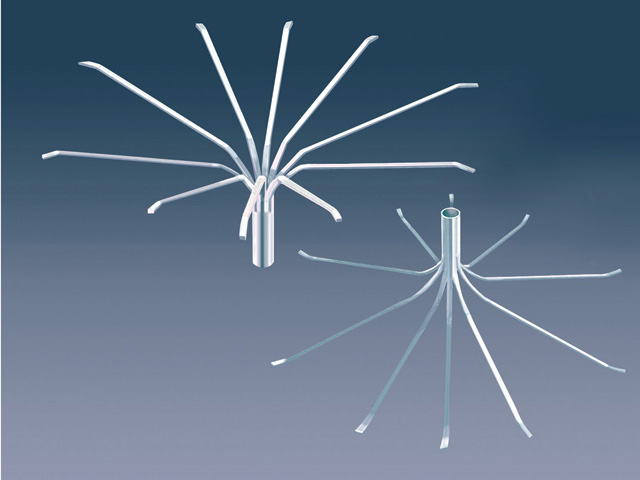

A better Arthroscopic Probe

The surgical device designer wanted a thin, lightweight probe that a surgeon could push through an artery then pull back, allowing a dozen extensions to spring out, conforming to curved or irregular arterial surfaces. The probe’s extensions had to be thin enough to fit in the very narrow probe and then, when the probe was pulled back, flexible enough to conform to the surfaces. Read more…