Evans’ deep drawn and progressive die Hastelloy stampings

Hastelloy is one of numerous superalloys stamped and treated at Evans.

Hastelloy is a nickel-molybdenum superalloy known for corrosion-resistance. Common Hastelloy grades are B and C. Hastelloy B is known for resistance HCl and for its creep and rupture strength at high temperatures, while Hastelloy C is known for resistance to active oxidizing agents. Hastelloy derivatives are found in many applications, such as aeronautics, construction materials, mobile devices, medical equipment, pharmaceuticals and food preparation.

Production of Hastelloy components is sophisticated and often avoided by companies specializing in metal stamping.

Working on a project using Hastelloy? If we can help, please click here.

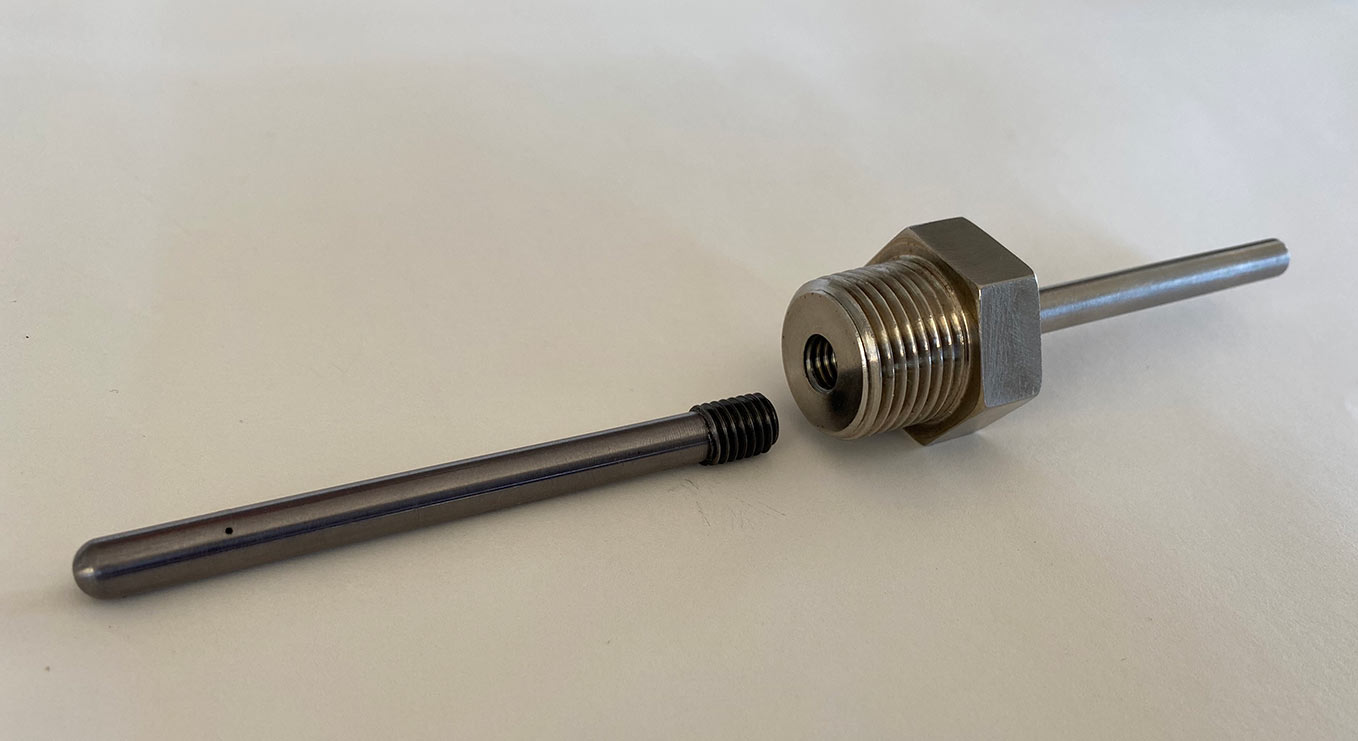

This test probe is a complicated three-piece metal assembly that continuously monitors an advanced CPI process that transports caustic chemicals.

At one end of the Evans assembly is a tantalum tube, machined to be hollow but closed at the end. The tube is immersed in a harsh chemical that flows through a pipe. A small hole, side-pierced into the tantalum tube, allows a chemical sample to be drawn into the Evans assembly from the center of the flow.

At one end of the Evans assembly is a tantalum tube, machined to be hollow but closed at the end. The tube is immersed in a harsh chemical that flows through a pipe. A small hole, side-pierced into the tantalum tube, allows a chemical sample to be drawn into the Evans assembly from the center of the flow.