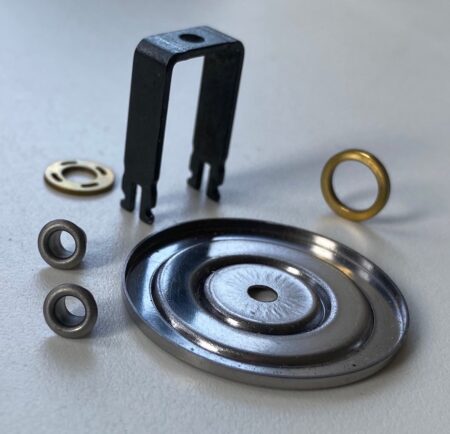

Deep drawn and progressive die metal stampings for electronics applications

Evans Company manufactures complicated deep drawn and progressive die metal stampings, including miniature, tight tolerance components for electronics.

Our deep drawn and progressive die metal stampings include miniature electronics components.

Our deep drawn and progressive die metal stampings include miniature electronics components.

ISO9001 certified

Parts for crimp sleeves and connectors, contacts, springs, RFI/EFI shields, tantalum capacitors, hermetic seal feedthrough tubes, hermetic packaging, subminiature tubing.

Metals

Refractory metals, including tantalum, titanium, niobium and molybdenum.

Reactive metals like beryllium and zirconium.

Elemental metals and alloys like aluminum and stainless steel.

Working on an electronics project? If we can help, please click here.

Evans did not stamp but machined this niobium nut plate with a fine 1.1mm thread. Niobium (columbium) was selected in part because of its stability at cryogenic temperatures, an important consideration in superconductor work.

This tantalum capacitor cap is part of a hermetically sealed can, also manufactured by Evans. Thousands of tantalum supercapacitor cases used in aviation and oil exploration have been made at Evans Technology.

This can, a teryllium copper alloy, is deep drwn and formed with two diameters. It is part of a telecom system that dissipates high-energy electrical spikes. The can features a tight-tolerance edge to seal tightly with precision-ground glass.