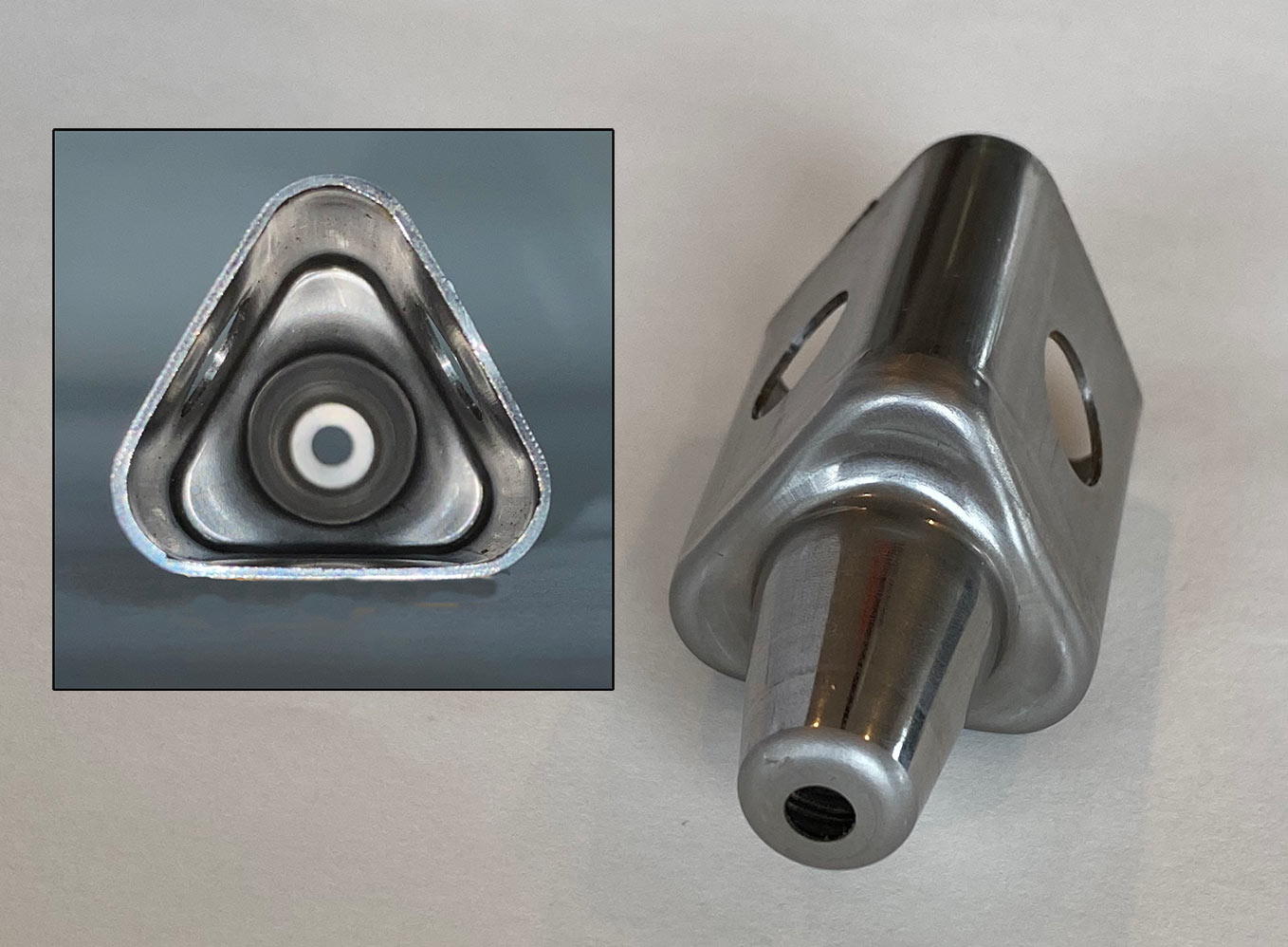

Evans Company manufactures deep drawn and progressive die metal stampings in exotic and common metals.

These include high precision, detailed miniature components for a broad spectrum of industries, from food, cosmetic and pharmaceutical processing to underground construction, aerospace transportation, and medical implants and devices.

We offer precision components for heat transfer systems, appliances, machinery, materials transfer equipment, pipelines, powertrains and pressure tubing.

We work in refractory metals, including tantalum, titanium, niobium, and molybdenum. We work in reactive metals like beryllium copper. And we work in elemental metals and alloys of copper, iron, niobium, tantalum, molybdenum, zirconium, platinum, aluminum, titanium, gold, silver, palladium, iridium, etc.

ISO9001:2015 certified

Working on a general industrial project? Any questions? If we can help, please click.